The main driver for this is often offsite manufacture, whether it be a timber frame construction or a pre cast plank system. Another key reason is fixing to existing slabs on old buildings.

Sapphire’s innovative range includes brackets for:

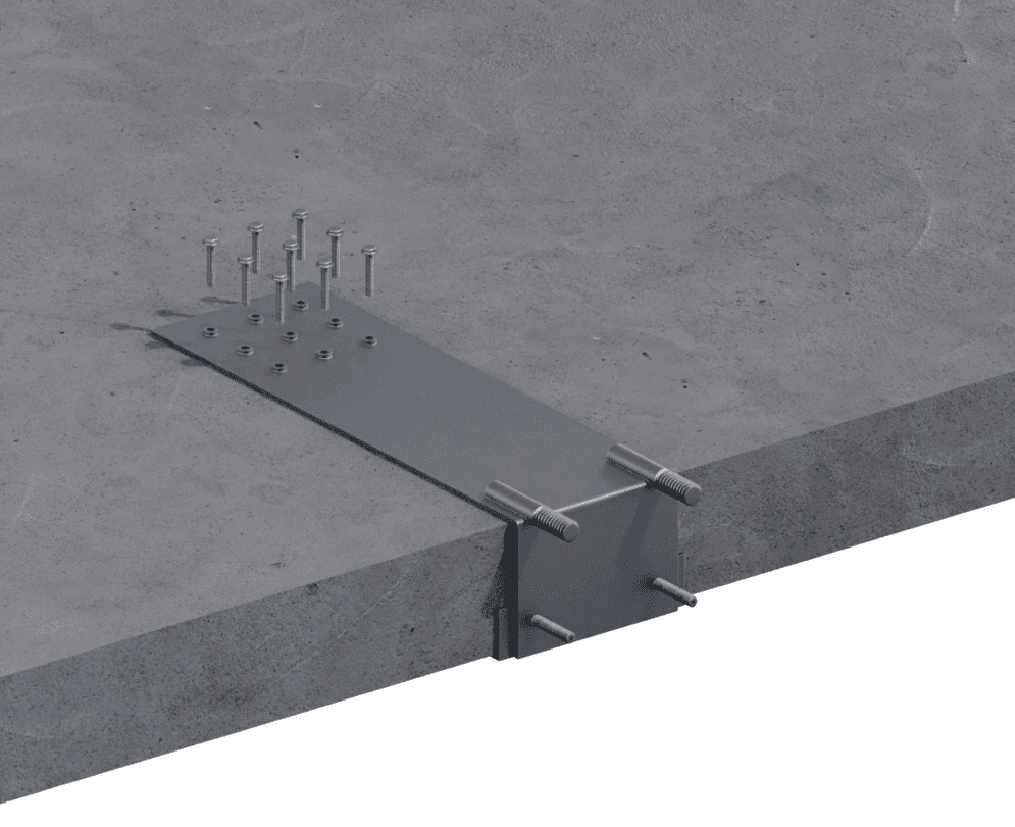

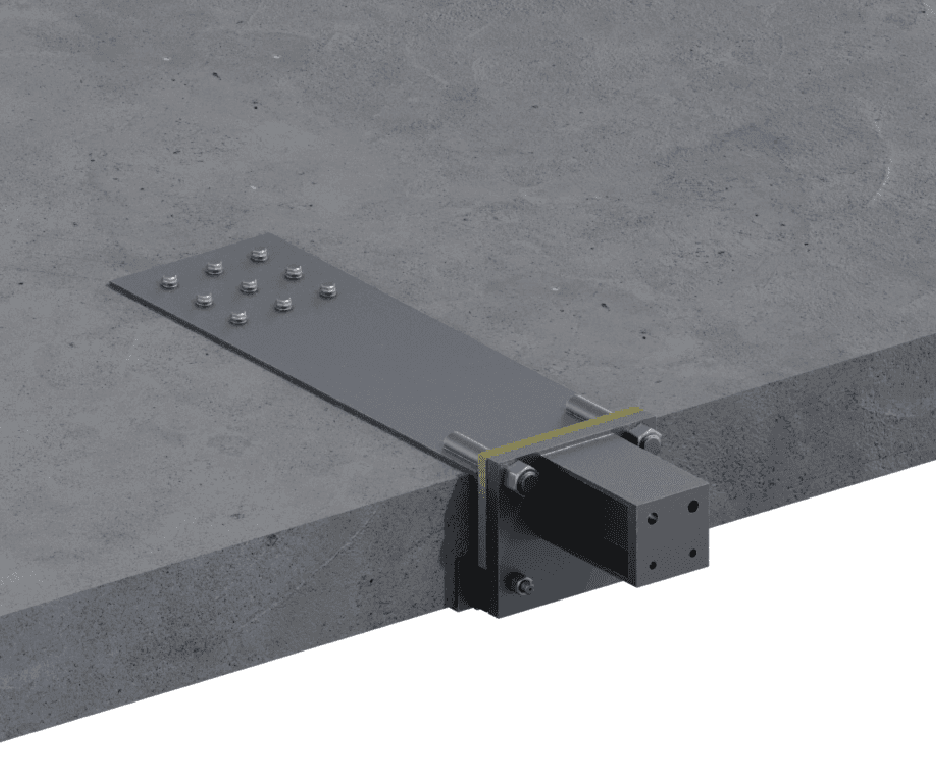

When using a hollow plank, the voids (or hollows) around the anchor should be filled with a structural grout. This is best practise to ensure the bracket is fully supported underneath and around it. We understand that planks layout are often not easily changed. We do however recommend that consideration should be made for where joints are, as this can make a considerable difference to structural fixings and performance.

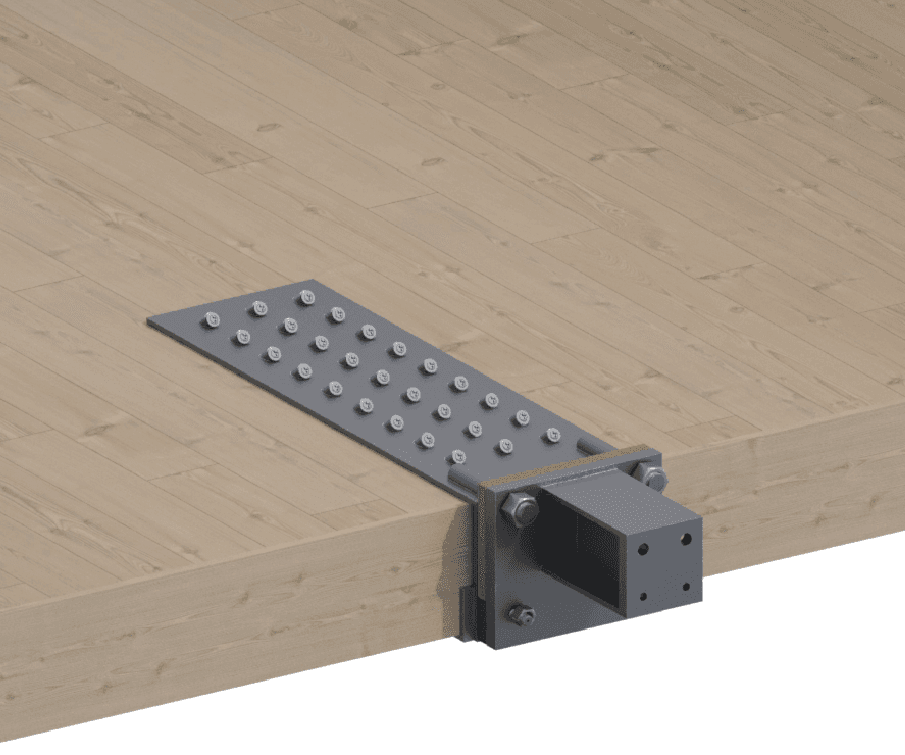

With cross laminated timber construction operating very different from concrete, the bracket design needs to be considerably different.

For the first timber frame project we installed, we learnt a lot about these differences through conducting a drawn out R&D program. This involved multiple tests and improving the performance of the bespoke connection to achieve an anchor which minimises the deflection on the balconies.